Industrial

In industrial process engineering, the unit operation of mixing involves manipulation of heterogeneous physical systems to make them homogeneous. ProSep’s proprietary mixing technologies have a proven track record of creating homogeneous streams in the Oil & Gas industry. These same benefits of reduced energy, optimized additive utilization, increased kinetics and on-line processing hold great promise for other industrial applications.

PROSEP MIXERS FOR INDUSTRIAL APPLICATION

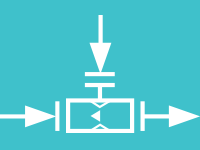

ECLIPSE | Enhanced Center Located Injection Pipe Spool

ECLIPSE evenly distributes injected fluid around the center located cone, then uses local dynamic pressure to create small droplets while increasing interfacial area for enhanced mass transfer.

ECLIPSE evenly distributes injected fluid around the center located cone, then uses local dynamic pressure to create small droplets while increasing interfacial area for enhanced mass transfer.

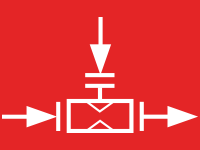

AIM | Annular Injection Mixer

In the AIM, injected fluid is forced into streams, then sheared into small droplets by the increasing local dynamic pressure of the main process flow, which provides dispersion and mixing into the production stream.

In the AIM, injected fluid is forced into streams, then sheared into small droplets by the increasing local dynamic pressure of the main process flow, which provides dispersion and mixing into the production stream.

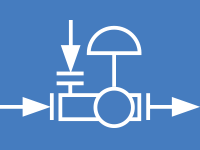

MAX | Multiphase Adjustable Xtreme Mixer

MAX homogeneously applies shear force to the dispersed phase of the main process flow, providing a narrow droplet distribution, and enhancing mass transfer with the ability to modulate with process fluctuations.

MAX homogeneously applies shear force to the dispersed phase of the main process flow, providing a narrow droplet distribution, and enhancing mass transfer with the ability to modulate with process fluctuations.

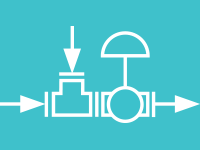

EBS | Enhanced Blending System

EBS is a combination of the Pre-Distribution Injector with the MAX. The even distribution of injected fluid allows for a quicker, more easily obtained homogeneous mixture.

EBS is a combination of the Pre-Distribution Injector with the MAX. The even distribution of injected fluid allows for a quicker, more easily obtained homogeneous mixture.

Interested in inquiring about ProSep’s mixing technologies?