ProSep Achieves Inter-Continental Growth & Success

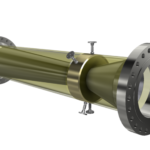

Emphasizing the impressive capabilities of its Multiphase Adjustable Xtreme (MAX+) mixer technology, integrated process solutions provider ProSep is on an impressive streak across…

Emphasizing the impressive capabilities of its Multiphase Adjustable Xtreme (MAX+) mixer technology, integrated process solutions provider ProSep is on an impressive streak across…

Building on a successful first half of the year, ProSep has announced the receipt of two contract awards totaling nearly 2 million USD. …

In a significant deal, ProSep has announced a landmark six-figure contract for the global leader in produced water solutions and mixing technologies to…

Industry-leading global provider of integrated process and mixing solutions, ProSep, has received official acknowledgment from the US Patent Office for improvements made to…

ProSep was thrilled to be part of the lineup of winners during EV Private Equity’s annual Investor Conference, announced as ‘ESG Company of the…

ProSep, the global leader in high efficiency mixing and water treatment solutions, has announced significant expansion in the Middle East through three new…

If you have any questions or would like to inquire about our products or services, please use this button to contact us.

Contact UsSubscribe to our mailing list for news & updates about ProSep and our new era of process separation solutions.

Sign up now