Downstream

Mixer and

Water

Solutions

ProSep’s high efficiency mixers and clean water technologies provide

beneficial solutions for a variety of downstream applications.

Downstream Mixer and Water Solutions

Explore ProSep

Eclipse

Aim

Max

Osorb

Torr

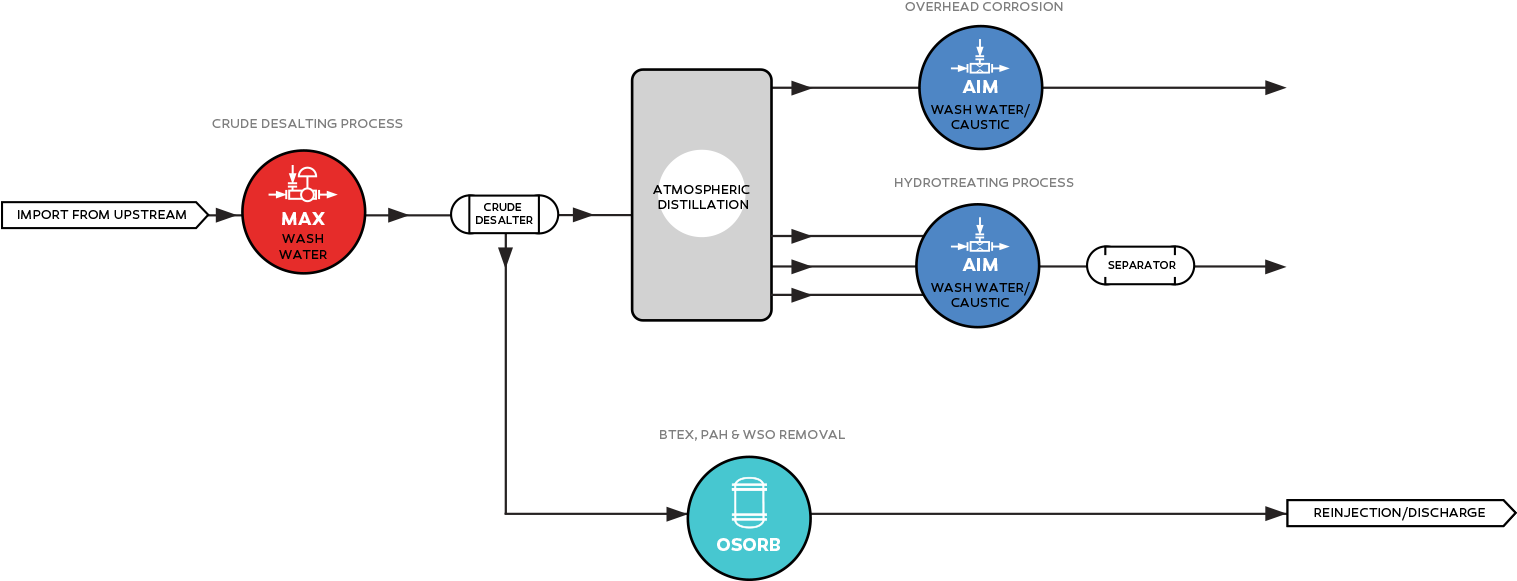

Crude Desalting

To minimize corrosion, the first treatment step in the refinery is crude desalting to remove associated salts before distillation and hydrotreating.

ProSep’s MAX+ improves the water wash mixing efficiency with the crude oil associated produced water, resulting in greater dilution yielding lower salt-in-crude levels after dehydration. Analyzing a large data base of desalting performance, the mixing efficiency for conventional systems (globe valves, static mixers, etc.) was found to be between 30 and 60%. When the MAX+ mixer was implemented, the resulting mixing efficiency was greater than 90%.

READ MORE

Overhead Corrosion

Distillation column overhead lines and downstream heat exchangers are often areas where corrosion cause refinery maintenance issues.

ProSep’s AIM injection mixer achieves 100% dispersion of wash water and reaches thermal equilibrium at the outlet flange of the unit, in a robust design where plugging or injection quill breakage is avoided. As water saturated gases containing corrosive ionic species cool, the water droplet “seeds” combine with the ions to prevent crystalline salt formation from occurring, thereby reducing corrosion or plugging issues.

READ MORE

Hydrotreating Processing

Hydrotreaters are an integral process unit in all refineries to remove impurities such as sulfur, nitrogen and metal content. Hydrotreater feeds need to be water washed to take out these salts.

ProSep’s AIM injection mixer provides homogeneous dispersions of the injected phase by the outlet flange of the unit, providing maximum wash water / caustic wash benefits with minimum usage to prevent the formation of NH4Cl and NH4HS and other acidic components.

READ MORE

BTEX and PAH Removal

As refineries improve their hydrotreating performance to reduce the levels of sulfur and other harmful components in their hydrocarbon products, these contaminants are often concentrated in the waste water treatment system.

ProSep’s OMS (Osorb Media System) utilizing Osorb media, a hydrocarbon adsorbent with a finite capacity that can be regenerated and reused, has demonstrated Best Available Technology (BAT), removing dispersed, emulsified and dissolved hydrocarbons, BTEX, PAH and WSOs.

READ MORE

HAVE A PROBLEM?

WE PROVIDE CLEAN SOLUTIONS.

Get MAX

If you have any questions or would like to inquire about our products or services, please use this button to contact us.