Upstream

Chemical

and Water

Solutions

ProSep’s high efficiency mixers and clean water technologies provide

beneficial solutions for a variety of upstream applications.

Upstream Chemical and Water Solutions

Explore ProSep

Eclipse

Aim

Max

Osorb

Torr

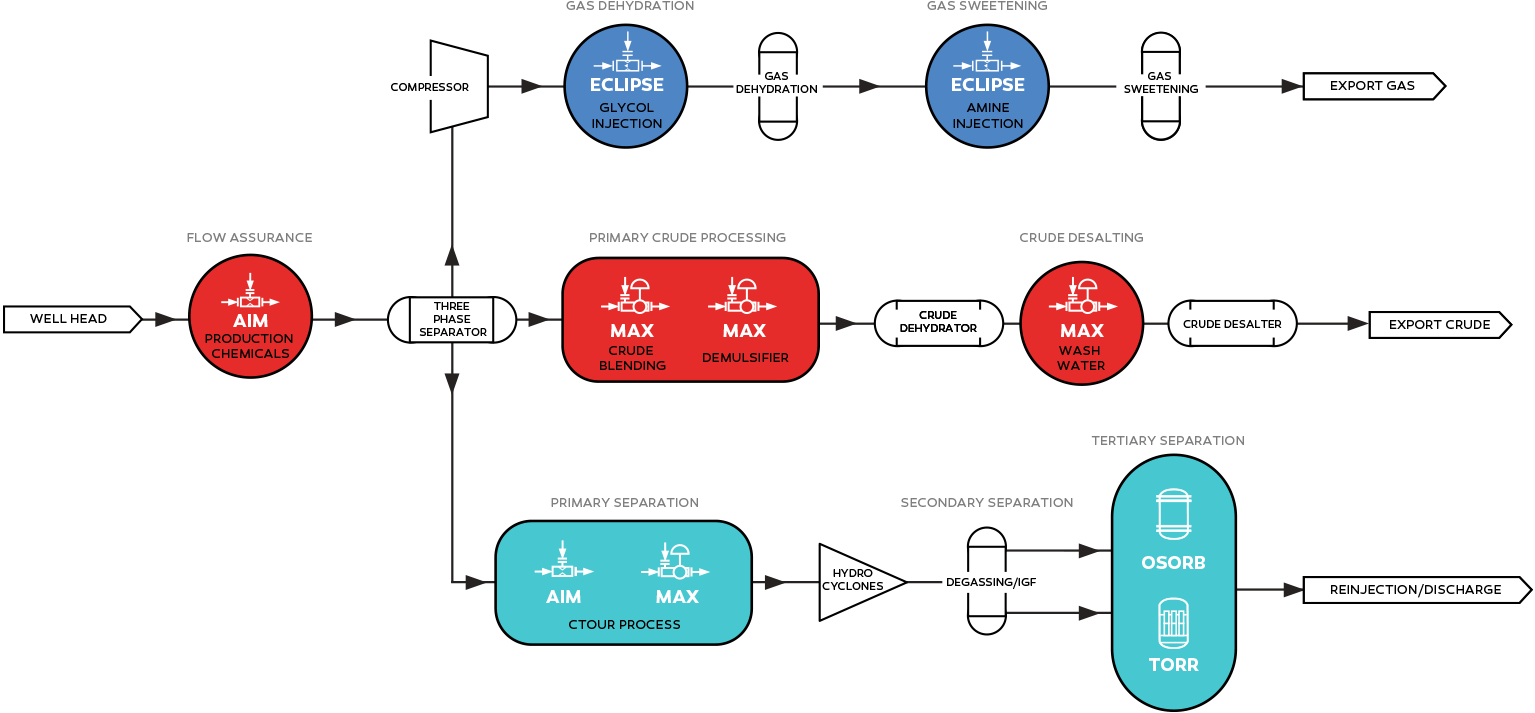

Flow Assurance

Once an oil or gas field is developed, one of the most significant cost elements contributing to OPEX are the production chemicals.

ProSep’s AIM injection mixer has a proven track record of maximizing the utilization of production chemicals; demulsifer, scavenger, scale inhibitor, etc., resulting in 20-60% savings and associated ROI’s in months/weeks.

READ MORE

Primary Crude Processing

Production facilities often are faced with changes in crude characteristics as field development progresses into different zones or reservoirs.

ProSep’s MAX+ homogenization mixer delivers completely blended crude mixtures at the outlet flange as a result of the unique blending cylinder. The MAX+ also optimizes demulsifier utilization as a result of the high level of mixing provided, significantly reducing chemical demand.

READ MORE

Crude Desalting

Crude pipeline and refinery specifications often require crude desalting in upstream production facilities.

ProSep’s MAX+ desalting mixer brings the next generation of desalting mixing technology to producers and refineries looking to improve their operational performance. After evaluating the desalting performance of a multitude of desalters, conventional systems were found to have between 30 and 60% mixing efficiency. The MAX+ desalting efficiency, specifically on upstream applications, achieved greater than 90% efficiency.

READ MORE

Gas Dehydration

Inevitably operators are pressed to increase production throughput while maintaining / improving performance of their natural gas dehydration system.

ProSep’s ECLIPSE injection mixers installed in the inlet of existing dehy systems have delivered an additional theoretical stage of dehydration. This improvement has offered operators a number of options; 1) the ability to reduce outlet water content, 2) reduce TEG regeneration duty, or 3) increase natural gas throughput.

READ MORE

Gas Sweetening

Acid gas components over pipeline or client specification can often result in production being shut in thereby interrupting operations and supply agreements.

ProSep’s ECLIPSE injection mixer can be utilized to selectively remove H2S from high CO2 streams, debottlenecking amine sweetening operations, eliminating amine solvent adsorption competition between these acid gas molecules.

READ MORE

Produced Water Primary Separation

Overboard produced water discharge compliance can be challenging to achieve, particularly if there are a significant amount of emulsified or dissolved hydrocarbons present.

ProSep’s CTour process, utilizing solvent extraction principles, has been successful in significantly reducing harmful components in produced water discharge. At one point, 2/3rd of the Norwegian produced waters, more than 2 million BWPD, were treated utilizing the CTour® process.

READ MORE

Produced Water Tertiary Separation

Overboard produced water discharge compliance can be challenging to achieve, particularly if there are a significant amount of emulsified or dissolved hydrocarbons present.

ProSep’s TORR coalescing units have a proven track record for breaking tight emulsions to produce effluent waters with less than 2 ppm in many instances. Additionally, ProSep’s OMS (Osorb Media System) has been recognized as the BAT (best available technology) for providing ALARP (as low as reasonably possible) produced water effluent quality.

READ MORE