Midstream oil

and Gas

Processing

ProSep’s high efficiency mixers and clean water technologies provide

beneficial solutions for a variety of midstream applications.

Midstream Oil and Gas Processing

Explore ProSep

Eclipse

Aim

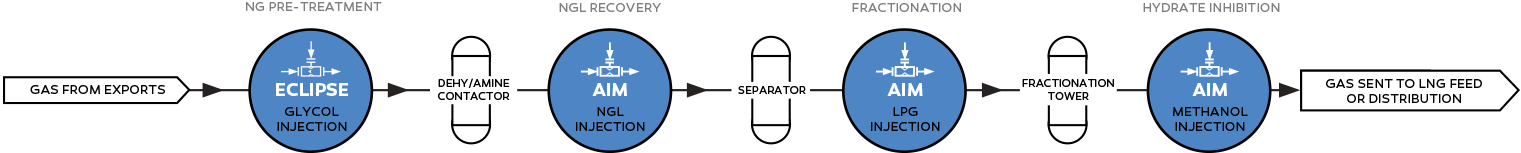

Natural Gas Pre-treatment

Midstream production facilities must be designed to process a range of inlet natural gas flow and quality conditions, requiring flexibility in design.

ProSep’s ECLIPSE injection mixer can add an additional theoretical stage of treatment to glycol dehy systems and amine sweetening units. Upwards of 20% increase in throughput, water dewpoint or reduction in reboiler duty has been demonstrated in several case studies.

READ MORE

NGL Recovery

Often there is more value in the NGL fractions than the natural gas, so midstream companies seek to optimize their NGL production.

ProSep’s AIM injection mixer can be utilized to replace C5+ reflux contact towers to maximize NGL recovery while reducing midstream facility complexity and capital intensity.

READ MORE

Frac Spread Optimization

As natural gas and liquid prices fluctuate due to commodity market demand, natural gas midstream facilities are tasked with maximizing revenue.

ProSep’s AIM injection mixer has been utilized to maximize NGL production by liquifying lighter fractions into NGL product streams as well as re-vaporizing NGLs into natural gas streams depending on the market demand and pricing for each commodity.

READ MORE

Hydrate Inhibition

Hydrate formation in production piping or equipment has the potential to disrupt operations and involve significant maintenance issues.

ProSep’s AIM injection mixer CFD modeling and field data have verified the injection mixer’s ability to create homogeneous dispersions of micron sized droplets by the outlet flange of the unit, providing maximum additive benefit with minimum usage.

READ MORE