Author: Nicole Miles

ProSep’s AIM high-efficiency mixer is featured in the June 2019 edition of JPT

ProSep’s AIM high-efficiency mixer is featured in the June 2019 edition of the Journal of Petroleum Engineering, JPT. Our AIM mixer delivers high…

A great start to Q2!

We are delighted to share that the start of Q2 has been fantastic! – four POs totaling close to $2 MM for the delivery of…

Meet the Expert: Tommie Jackson!

Next up as part of our meet the expert profile series is Tommie Jackson. Tommie joined ProSep in 2017 as a Product Development Field…

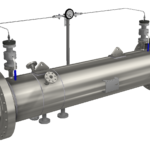

ProSep set to deliver MAX+ ProSalt mixers to Heimdal Platform

ProSep has successfully secured a contract with Aker Solutions to provide two MAX+ ProSalt™ mixers to Equinor’s Heimdal Gas Centre Platform in the North Sea….

May 2019 Internal Strategy and Technical Session

ProSep held their semi-annual Strategy and Technical Session in Houston. The session kicked off with two inspiring keynote speeches from Ryan Gurney, Managing…

ProSep’s Multiphase Adjustable Xtreme Mixer (MAX+)

Our Multiphase Adjustable Xtreme Mixer (MAX+) technology offers homogenous, high efficiency mixing which can be utilized for desalting, chlorination, demulsifier injection and scavenging….

If you have any questions or would like to inquire about our products or services, please use this button to contact us.